- ARTICLE

- CROP MANAGEMENT

- WEATHER

What Is the Best Weather for Crop Spraying?

Spraying your crops in poor weather conditions can waste chemicals, increase costs, and harm...

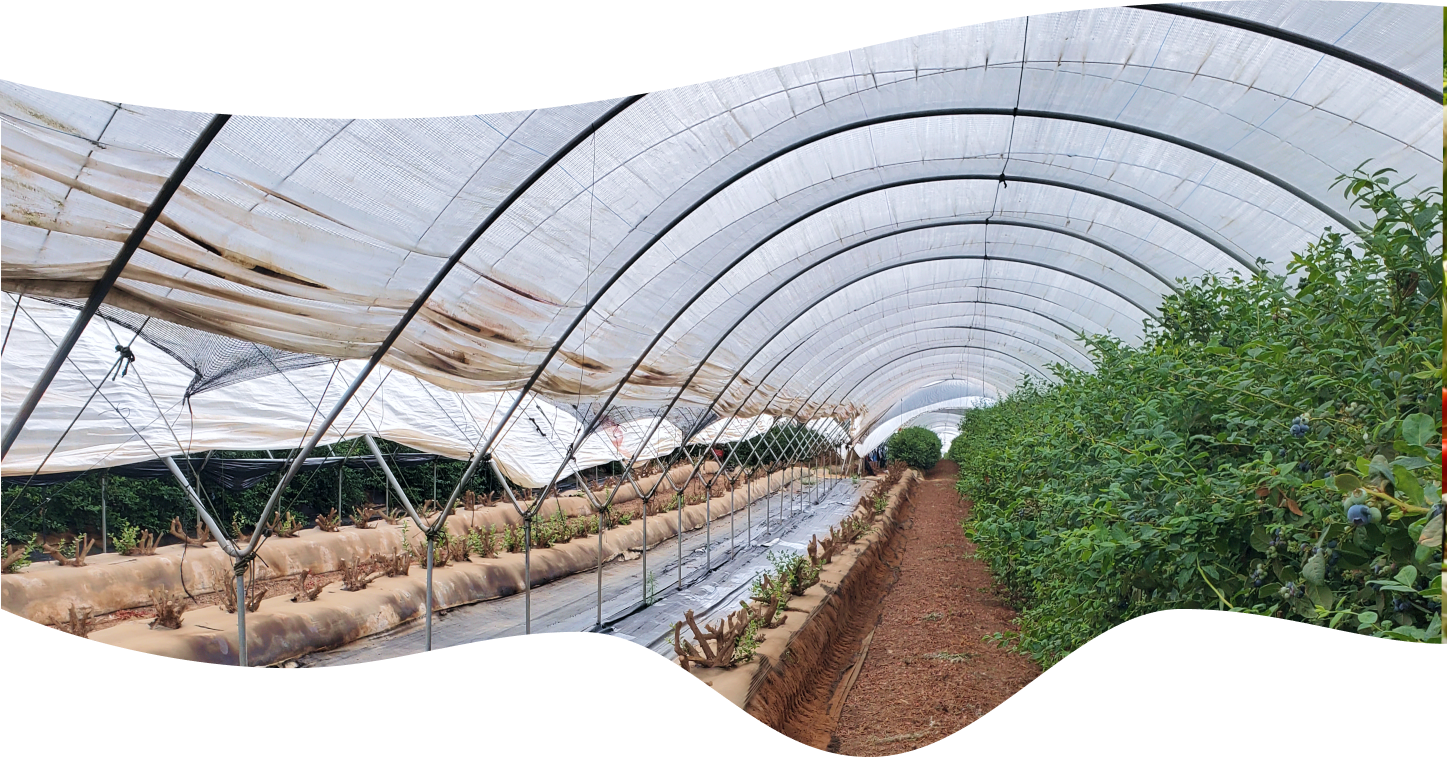

Aziz El Kahlaoui is African Blue’s Horticultural Manager and has worked at the company since 2007. One of his major challenges was the accessibility of climate and plant health data across all nine farms to inform farm management decisions. In October 2022, African Blue turned to WayBeyond’s FarmRoad digital agronomy solution as the single platform to continuously monitor and visualise their farms' climate and plant health data. Now, Aziz can make timely decisions without having to travel to every farm.

Guillermo DiGuiseppe, Agronomist, Season Farms

Guillermo DiGiuseppe is the agronomist and crop manager at Season Farms. During summer months he noticed the high temperatures were having a negative impact on production and investigated further.

Although air temperature was being monitored, air temperature is only a proxy for plant temperature, and an approximate one at that. In some cases the difference between the two can be as much

as 7°C. Guillermo noted:

“Many sensors only provide an approximation of plant temperature, they can’t tell you the actual plant temperature. We see a clear difference between air temperature and the temperature of the strawberry leaf. It would be better to have a temperature sensor on the leaf rather than a general air sensor”.

Season Farms' Crop Manager and Agronomist Guillermo DiGiuseppe

Season Farms' Crop Manager and Agronomist Guillermo DiGiuseppe

So using an infrared thermometer, he measured leaf temperatures of several plants over the course of a typical summer day. He discovered these temperatures were getting up to as high as 35°C, resulting in overly stressed plants.

Plants experiencing high temperatures close their stomata to conserve water, but by doing so sacrifice their ability to cool themselves through water evaporation. Thus, extreme plant temperatures reduce the productivity of the plant.

This information provided a strong business case for the farm to implement whitewashing of the greenhouses. This method is commonly used to reduce heat and light during the hotter summer months. The whitewashing was conducted shortly after Guillermo’s discovery.

The solution came in the form of FarmRoad sensors. Six sensor units were deployed after the whitewashing implementation to monitor the plant temperature and radiation levels, both inside and outside. The FarmRoad unit's external plant temperature sensor coupled with its built-in PAR and RAD sensors meant that everything Guillermo needed to track was monitored continuously. Most growers capture light readings from sensors outside of the greenhouse. Having light sensors inside enables the grower to observe how much light loss can be attributed to their glass, plastic or whitewash.

Using the data provided by the FarmRoad sensors, the farm was able to conclude that the implementation of the whitewash had increased production by 20-30% and an increase in strawberry fruit size. Moreover, FarmRoad was able to show the reduction in radiation light by comparing the inside radiation with the outside radiation. (Fig. 1) It also showed that plant temperature barely exceeded 30°C throughout the hottest summer period, a positive outcome of their solutioning. (Fig. 2)

These two metrics combined with the production increase, proved the value of the whitewashing and validated their decision to invest.

Moving forward from the business case analysis of whitewash, Guillermo sees other benefits of using FarmRoad. Due to changing climate/seasonal temperatures, Season Farms want to dial in the timing of whitewash application – in future it may be pushed earlier or later, depending on what the plant data reveals.

Being able to monitor the metrics of air temperature, inside radiation and plant temperature will provide these insights for a timely application. The team at Season Farms are confident that FarmRoad will continue to help them improve crop productivity.

Spraying your crops in poor weather conditions can waste chemicals, increase costs, and harm...

Daniel Than, Customer Success Director at WayBeyond, explains why actionable climate insight—not...

.png)

Learn how to manage weather-related risks for your crops using an early warning system such as...

WayBeyond’s new GrowPilot app brings artificial intelligence into the hands of small to...

From cutting water use in drought-hit regions like Morocco to preventing thousands in losses from...

When faced with crop losses due to climate events and system failures, Eliven Tropical turned to...

A leading Moroccan berry grower cut water use by 16% using climate data and ETo-based irrigation....

ETo forecasting is a simple but powerful tool for optimizing irrigation every day, in every season....

See the strategy behind evapotranspiration-based irrigation planning that helped a greenhouse...

Learn how a people-first approach to change management empowers growers to successfully transition...

The grower's guide to using data for effective crop management. Get practical tips to achieve...

With late blight causing crop loss and large costs, Agrícola Chaparral turned to digital agronomy...

Learn how six key weather data points can help you make smarter irrigation decisions, conserve...

A smart approach to water management is key to helping growers tackle water scarcity and climate...

With over 470 ha of blueberry production, African Blue needed to unify farm data to improve crop...

Uncover the vital role of drip and drain monitoring in optimizing drip irrigation farming.

Explore how protected cropping growers can use data insights to drive smart irrigation practices.

Heat stress is a significant concern for berry growers as it has both positive & negative effects...

Real-time alerts play a vital role in empowering growers to make better crop management decisions.

Real world examples of common issues faced by growers that can be solved with real-time data,...

The protected crop growers guide to successfully managing your plants, team, practices and...

SaaS adoption in horticulture: discover challenges and pitfalls for both growers and technology...

Frost devastates blueberry crops, leading to significant economic losses. By harnessing digital...

Digital agronomy insights helps tackle crop loss, production variations, and declining yield by...

3 production problems that can be solved by collecting data: cross loss from disease, poor crop...

Discover the true cost of a fungal disease outbreak in crops, how to respond and the financial...

With protected agriculture on the rise, Mexico is ripe for the next wave of tech innovation.

Get insights on Integrated Pest Management planning for effectively managing infestations.

Learn how to manage plant stress and improve crop performance with Vapour Pressure Deficit.

Harnessing FarmRoad enabled to monitor the status of their crops and the farm as a whole and...

Why do growers use crop registration and how does it benefit crop management practices?

Growers require frequent and detailed climate data and crop status visibility to get the best from...

The agronomist at Season Farms noticed a drop in production and turned to WayBeyond's digital...

Plant pathology is the study of plant diseases and how they interact with plants. In this in-depth...

While the popularity of hand held moisture meters for plants shows no signs of abating, there are...

Champions of crop management.

Giving commercial growers the power to make better crop management decisions and optimize crop outcomes.

Solutions

Customers

©2025 WayBeyond. All Rights Reserved.