- ARTICLE

- CROP MANAGEMENT

Understanding Botrytis and How Growers Can Prevent It

Learn how to prevent Botrytis (gray mold) from damaging your crops with early detection and simple,...

03.12.2025 | 3 min

Crop spraying is one of the most important tasks for any farmer, which involves applying crop protection products to prevent and control pests and diseases, and fertilizers to supplement the nutrients plants need to grow. While there are a number of factors that determine the right time to apply these agrochemicals, the suitability of the weather is a critical one to consider. Key weather factors such as wind, rainfall, air temperature and relative humidity all play a significant role.

In this article, we’ll explore why each of these factors matter for agricultural spraying, and how growers can time their applications safely and effectively to get the best outcome for their crops.

One of the major recurring expenses for farmers is the use of chemical pesticides and fertilizers, so understanding how weather affects crop spraying is essential for optimizing these inputs.

In the U.S. alone, farmers spend over $20 billion a year on chemical inputs to protect their crops from pests and disease. Yet a staggering portion of pesticides miss their mark due to poor spray timing. When weather conditions are suboptimal, sprayed products can drift off target, evaporate before being absorbed, or run off plant surfaces onto the soil, where they end up in streams and waterways, often causing serious pollution.

When pesticide applications are timed effectively, it cuts chemical waste, lowers costs, reduces environmental impact and, more importantly, enables better pest and disease management to maintain crop health and yield.

Weather conditions such as wind, rainfall, air temperature, and relative humidity can directly influence the outcome of spray applications.

Let’s break down these weather parameters for safe and effective crop spraying:

Wind is the most important factor to consider when it comes to crop spraying. High wind speeds greatly increase the risk of spray drift, which is the movement of spray droplets away from the target plant and onto neighbouring fields or sensitive areas. This can lead to wasted chemicals, as well as potential damage to non-target crops and the environment,

However, strong winds aren’t the only concern. Wind speeds below 5 km/h (3 mph), or “dead calm”, as growers call it, often coincide with adverse spraying conditions such as temperature inversions, where the potential for drift is high.

Generally, a gentle, steady breeze of around 5-15 km/h (3-10mph) provides the ideal wind conditions for spraying, allowing droplets to deposit evenly on the crop while reducing the risk of off-target movement.

| Suitability for spraying | Wind speed (km/h / mph) |

|

Good/ideal |

Light to gentle breeze ~ 5-15 km/h (3-10 mph) |

|

Average |

3-5 km/h (2-3 mph) or 15-20 km/h (9-12 mph) |

|

Poor/unsafe |

Calm ~ below 3 km/h (2 mph) or High wind ~ above 20 km/h (12 mph) |

Wind speeds and suitability for crop spraying

The direction of the wind is just as important as its speed. For safe spraying, the wind should move toward the intended target area while staying clear of susceptible crops..

💡Grower Tip: Keep an eye on the expected wind speed and direction, and when these changes are likely to occur throughout the day. Aim to avoid spraying during strong winds and dead calm conditions to minimize the risk of pesticide drift.

Rainfall is another critical factor affecting spray timing and can influence the effectiveness of chemicals after they’re applied. Most pesticides, along with some fertilizers, need a specific amount of time to dry and be absorbed by the plant, known as the rainfast period, which can be found on the product label.

If it rains before this period is complete, the applied product can be washed off the plant before it’s fully absorbed. Wet leaf surfaces after rainfall can also make it harder for spray droplets to stick, limiting the treatment’s effectiveness.

💡Grower Tip: Monitor short-term forecasts for the likelihood of rain. Delay spraying if light rain (under 5mm) is expected within the rainfast period, and allow at least 24 hours after heavy rainfall for soil conditions to stabilize and leaves to dry completely before beginning treatment.

Air temperature and relative humidity work together to determine how quickly spray droplets evaporate after application, affecting both coverage and uptake on the plants.

Hot and dry conditions increase the likelihood of spray drift because droplets evaporate faster and shrink into finer particles that are easily carried off-target. This rapid evaporation can also concentrate the active ingredients in crop pest control products, which may lead to phytotoxicity and damage to the plant - one reason why agrochemicals specify upper temperature limits on their labels.

Cooler, more humid air, on the other hand, is more favorable for crop spraying as it slows the drying of spray droplets on the leaf surface, giving the chemical more time to be absorbed by the plant.

Growers can use a measure like Delta-T to assess the rate of spray evaporation. High Delta-T values indicate rapid droplet evaporation and an increased risk of drift, while very low values signal slower drying and a greater chance of the spray being washed off. As a general rule of thumb, a Delta-T between 2 and 8 is considered ideal for spraying.

Delta-T is calculated using the formula:

ΔT = Dry Bulb Temperature – Wet Bulb Temperature

This means you need two temperature readings: the dry bulb temperature (normal air temperature) and the wet bulb temperature (air temperature influenced by humidity). The difference between these values gives you the Delta-T.

To get Delta=T levels for spraying, growers can use a weather tool such as a handheld meter or an on-farm weather station, which automatically calculates Delta-T based on air temperature and relative humidity readings.

💡Grower Tip: Don’t rely on one weather measure alone before spraying. Pay attention to air temperature and relative humidity levels, using a value like Delta-T to assess conditions.

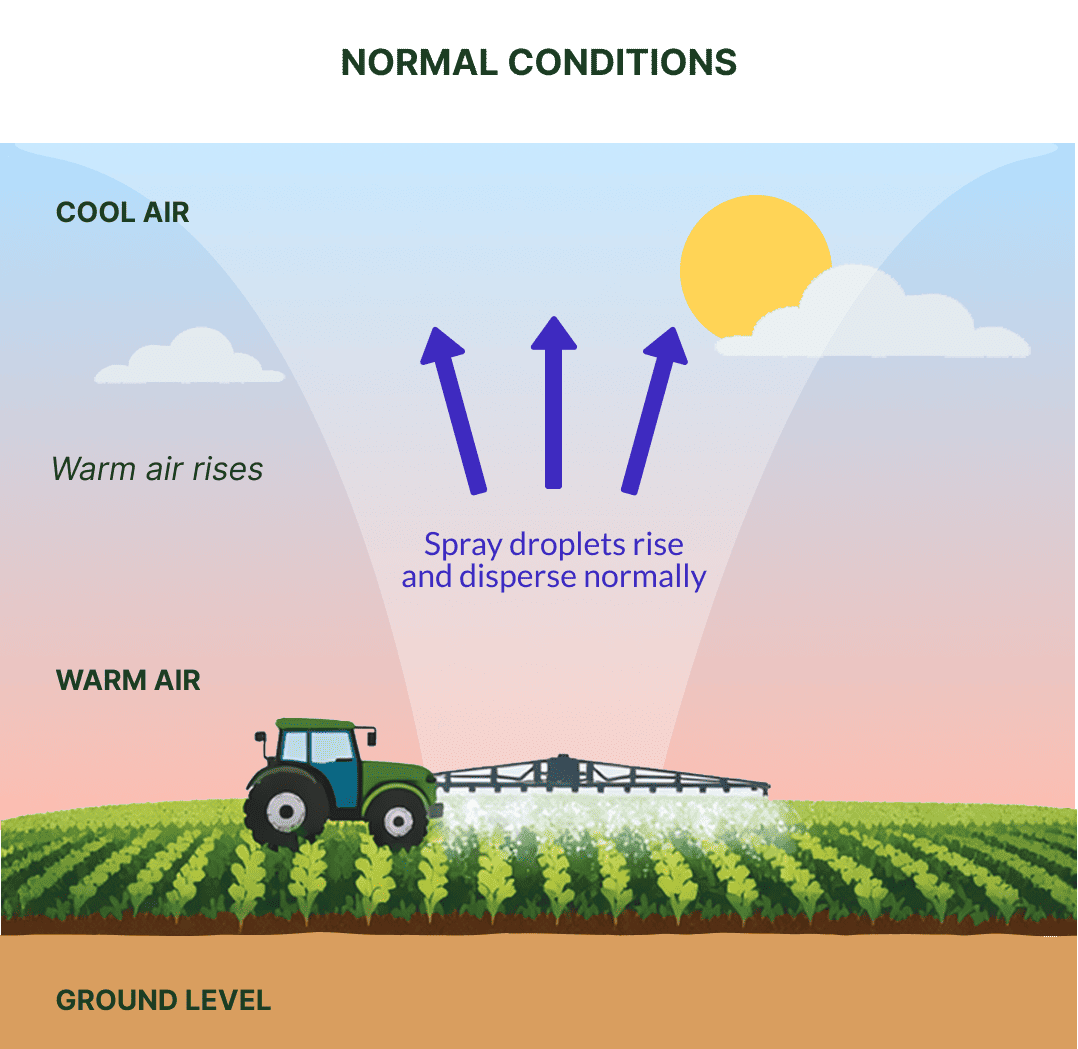

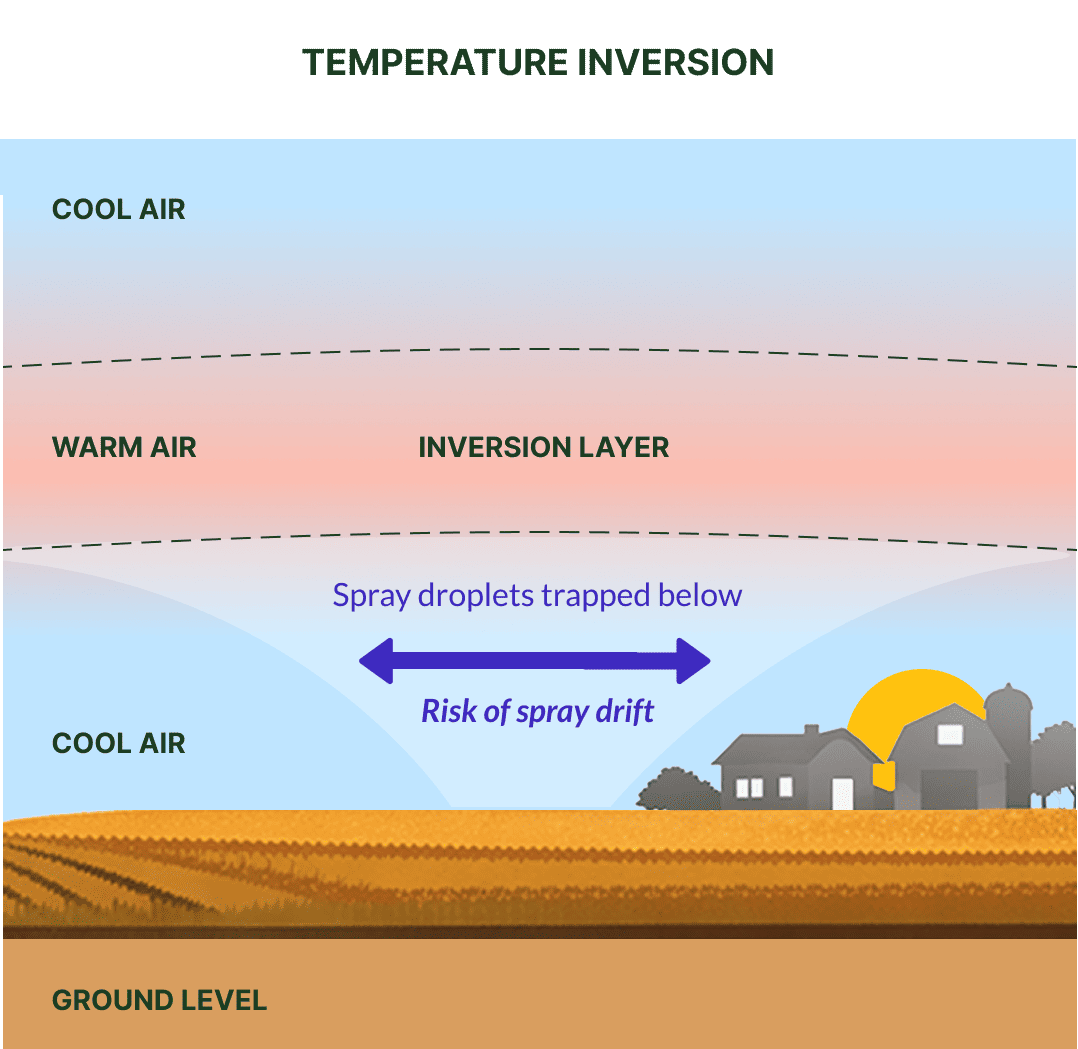

Temperature inversions can create hazardous conditions for spray drift. Under normal conditions, the temperature of the air gets colder at higher altitudes. But during an inversion, a layer of warmer air settles above the cooler air near the surface, limiting vertical air movement and preventing spray droplets from dispersing as they normally would. When this happens, droplets remain suspended in the air and can travel long distances from the target area once the inversion breaks.

While temperature inversions may develop at any time of the day, they are most likely to form during clear, calm evenings, and may persist into early morning.

💡Grower Tip: Fog, smoke or dust lingering near the ground are useful indicators of a temperature inversion. During an inversion, it’s best to delay spraying until the surface air begins to warm or light winds return (above 5 km/h or 3 mph).

Accurate, real-time weather monitoring helps growers identify suitable windows for spraying, eliminating guesswork.

Tools like WayBeyond’s GrowPilot app give growers localized forecasts and current field insights, allowing them to act on the latest information and anticipate changes in weather conditions.

While navigating the unpredictable nature of the weather is a challenge, having reliable forecast data to work with is the crucial first step toward smarter, more effective spraying.

Missed our blog on managing weather risks for your crops? Catch up here.

Learn how to prevent Botrytis (gray mold) from damaging your crops with early detection and simple,...

.png)

Discover how growers use predictive alerts to manage crop risks from frost, diseases, and extreme...

Spraying your crops in poor weather conditions can waste chemicals, increase costs, and harm...

Daniel Than, Customer Success Director at WayBeyond, explains why actionable climate insight—not...

Learn how to manage weather-related risks for your crops using an early warning system such as...

WayBeyond’s new GrowPilot app brings artificial intelligence into the hands of small to...

From cutting water use in drought-hit regions like Morocco to preventing thousands in losses from...

When faced with crop losses due to climate events and system failures, Eliven Tropical turned to...

A leading Moroccan berry grower cut water use by 16% using climate data and ETo-based irrigation....

ETo forecasting is a simple but powerful tool for optimizing irrigation every day, in every season....

.png)

From breeding climate-resilient berry varieties in Australia to testing precision irrigation...

See the strategy behind evapotranspiration-based irrigation planning that helped a greenhouse...

Costa Group is using WayBeyond’s FarmRoad platform to support its elite blueberry breeding program...

Soil systems around the world are under pressure. Pollution, climate extremes and unsustainable...

AgTech enters 2025 with strategic investments prioritizing long-term food security over quick...

Our newsletter explores the evolving world of agriculture through the lens of innovation, insight,...

Darryn shares how digital agronomy and AI-powered solutions help farmers optimize production,...

Learn how a people-first approach to change management empowers growers to successfully transition...

The grower's guide to using data for effective crop management. Get practical tips to achieve...

Darryn Keiller shares his thoughts on the urgent need to rethink farming, tackle regional...

The HM.CLAUSE Kenya seed production team faced several challenges in optimizing their yield...

With late blight causing crop loss and large costs, Agrícola Chaparral turned to digital agronomy...

Learn how six key weather data points can help you make smarter irrigation decisions, conserve...

Two weeks, three countries, and ten customer farm visits later, Daniel Than, WayBeyond’s Customer...

A smart approach to water management is key to helping growers tackle water scarcity and climate...

With over 470 ha of blueberry production, African Blue needed to unify farm data to improve crop...

What if tomato seeds were treated as commodities? This article explains how data and AI can help...

Uncover the vital role of drip and drain monitoring in optimizing drip irrigation farming.

Explore how protected cropping growers can use data insights to drive smart irrigation practices.

.png)

Learn how Khawla Derstaouieh embraces digital agronomy to optimize irrigation, track pests, and...

Heatflation is rising food prices caused by extreme heat from climate change. How can protected...

Heat stress is a significant concern for berry growers as it has both positive & negative effects...

Do growers focus too much on high accuracy yield forecasting and miss key contextual indicators?

Discover how Sanaa Elmarini enhances decision-making in blueberry crop management at African Blue...

Practical solutions for today’s challenges in the world of horticulture. From real-time data to...

Real-time alerts play a vital role in empowering growers to make better crop management decisions.

Darryn addresses the importance of food security, how the pandemic showed a real vulnerability in...

Real world examples of common issues faced by growers that can be solved with real-time data,...

In this crop steering guide, you'll learn how to adjust environmental factors for ideal plant...

Fruit Logistica 2024 in Berlin wrapped last week, bringing to a close its biggest edition yet with...

Discover strategies for maximizing crop yields by balancing generative/vegetative growth.

The protected crop growers guide to successfully managing your plants, team, practices and...

The future of farming may be indoors. We know that’s already happening for tomatoes and leafy...

Read our team's report on the 2023 Morocco Berry Conference, held in Agadir.

Learn how interpreting crop yield prediction with contextual data improves decision-making and...

WayBeyond's team share first impressions, general observations and key takeaways from Fruit...

SaaS adoption in horticulture: discover challenges and pitfalls for both growers and technology...

Frost devastates blueberry crops, leading to significant economic losses. By harnessing digital...

Digital agronomy insights helps tackle crop loss, production variations, and declining yield by...

Lee Kirsopp challenges the need for high accuracy yield prediction. Can other data provide better...

Insights and reflections from the WayBeyond team at GreenTech Americas 2023, held in Querétaro,...

3 production problems that can be solved by collecting data: cross loss from disease, poor crop...

WayBeyond's study unveils factors behind yield swings and proposes an alternative to improve yield...

Discover the true cost of a fungal disease outbreak in crops, how to respond and the financial...

With protected agriculture on the rise, Mexico is ripe for the next wave of tech innovation.

Get insights on Integrated Pest Management planning for effectively managing infestations.

Learn the challenges and potential of AI and machine learning in agriculture for sustainable crop...

Read the round up of Berlin Fruit Logistica 2023 from the WayBeyond team on the ground.

Learn how to manage plant stress and improve crop performance with Vapour Pressure Deficit.

Harnessing FarmRoad enabled to monitor the status of their crops and the farm as a whole and...

Why do growers use crop registration and how does it benefit crop management practices?

Our food systems face uncertainty in the wake of Climate Change. Cyclone Gabrielle highlighted the...

Growers require frequent and detailed climate data and crop status visibility to get the best from...

The agronomist at Season Farms noticed a drop in production and turned to WayBeyond's digital...

Plant pathology is the study of plant diseases and how they interact with plants. In this in-depth...

While the popularity of hand held moisture meters for plants shows no signs of abating, there are...

Lotte Bayly shares about her career journey, navigating gender bias, and her views on gender...

Champions of crop management.

Giving commercial growers the power to make better crop management decisions and optimize crop outcomes.

Solutions

Customers

©2026 WayBeyond. All Rights Reserved.